Responsible production with respect for the natural material

All Wooden Magic products are made from high-quality birch plywood grade B/BB (mainly sourced from Latvia) and solid wood – beech, aspen, or linden (sourced from Bulgaria). Wood is a natural material with its own character – it gives each piece its uniqueness, but also comes with certain natural features.

We work with great attention to detail and a high level of sanding to ensure both safety and aesthetics – especially important for products intended for children. However, as with all handcrafted and natural products, rare cases of defects may occur, which we readily accept as valid complaints by either replacing the item or issuing a refund.

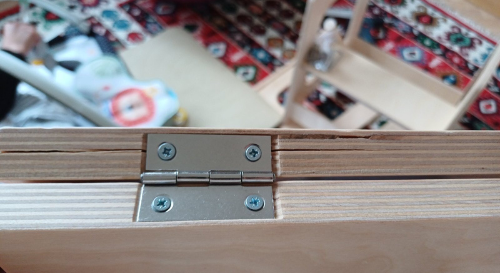

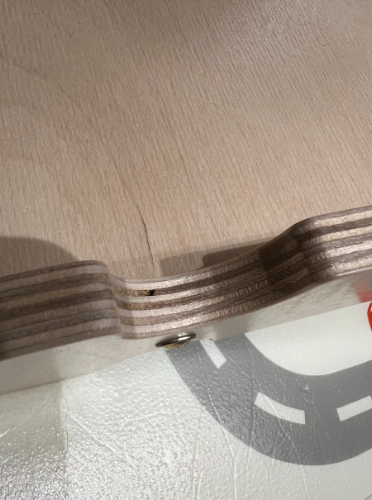

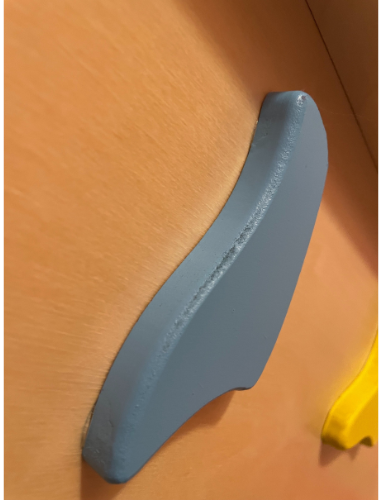

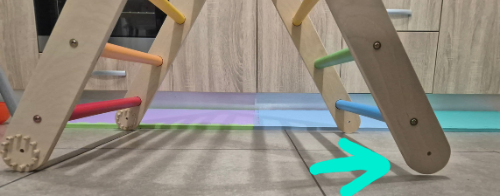

That said, we have also encountered situations where completely natural characteristics of the wood have been mistaken for manufacturing defects. That’s why we’ve created a detailed guide with photos to clearly show what is considered acceptable when working with wood and what is a genuine manufacturing fault that we take responsibility for.

Thank you for your trust and for appreciating handcrafted products and natural materials as much as we do.

P.S. Please note that the complaints we have shared are isolated cases, occurring once in thousands of orders, and many of the issues have already been resolved.